Hydraulic Hose Fittings

43 Series Hose Fittings 71 Series Hose Fittings 73 Series Hose Fittings HY Series Hose Fittings 78 Series Hose Fittings

Adapter

37 JIC Fittings Male Pipe Fittings O-Ring Face Seal Fittings O-ring Boss Fittings CD61&CD62 Flange Fittings

Quick disconnect Couplings

ISO 7241-A ISO 7241-B ISO 16028 Face-Seal

Test Point

37 JIC Connection 24 DKO Connection ORFS Connection Stud Connection

Push-On Fittings

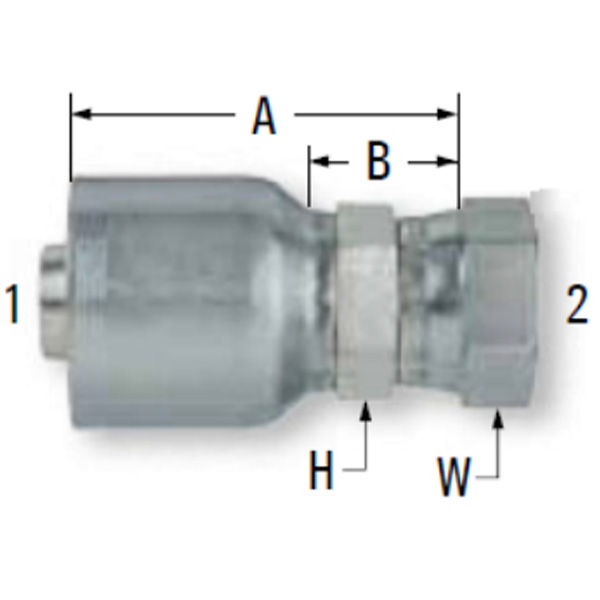

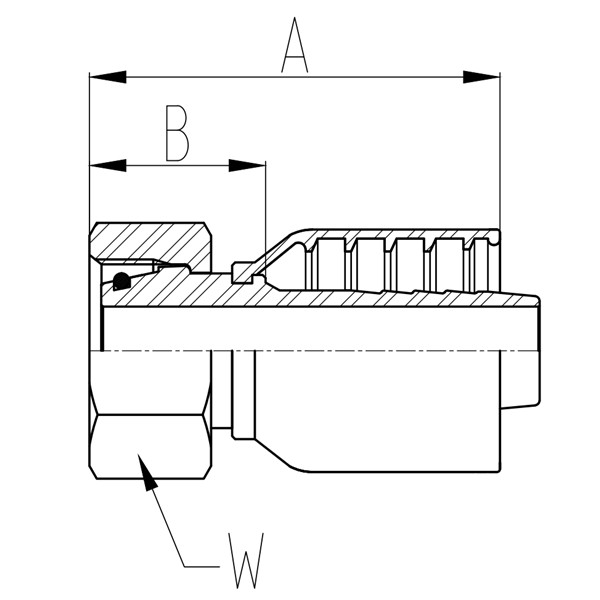

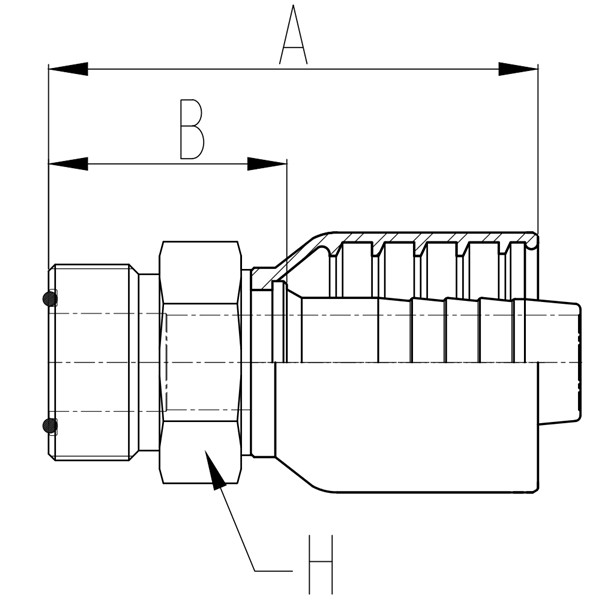

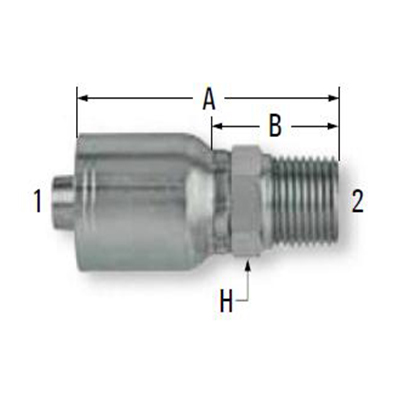

Male Pipe NPTF Hose Splicer Female JIC Swivel Male JIC 37

Hydraulic hose

Briaded hose - 1SN/ 100R17 / 1SC Briaded hose - 2SN/ 100R16 / 2SC 4 Wire hose - 100R12 / 4SP / 4SH 6 Wire hose - 100R13 / 100R15 Thermoplastic hose - 100R7 /100R8

about usabout us

HAINAR Hydraulics CO., Ltd. commenced manufacturing hydraulics hose fittings, adapters and hydraulic hose assembly in 2007, Our product range and main product line is for High-pressure hydraulic fittings and hose assembly.

After 14 years develop, HAINAR Hydraulics got a good reputation in domestic customer and oversea customers. We supply the hydraulic high-pressure hose assembly and fittings to machinery factory in domestic market. Such like injection molding machine, Construction machinery, mining machinery and drilling machine Fishing Equipment for ship etc. Now we have 40% of our hydraulic hose fittings, adapters and hydraulic quick couplings are exported to Western Europe, Eastern Europe, North American, South American and South East Asia.