In the highly complex and precise industrial field of automobile manufacturing, material selection is crucial for ensuring vehicle performance, durability, and safety. PTFE hose play an indispensable role in automotive manufacturing due to their unique performance advantages. This article aims to explore the key applications of Teflon hose in automotive manufacturing and the many benefits it brings to the automotive industry.

1、 Performance advantages of Teflon Hose

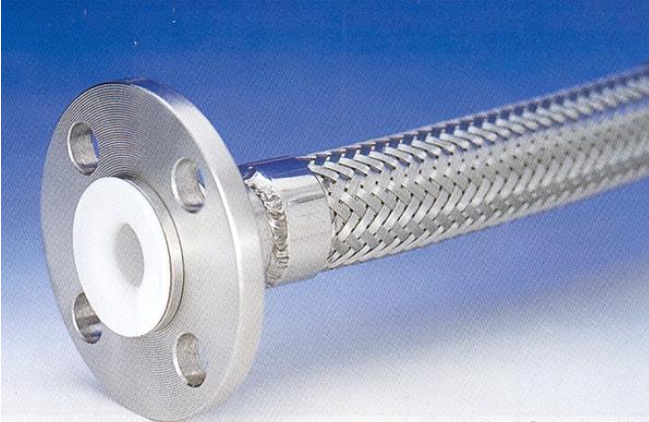

Teflon hose, as a high-performance polymer material, is renowned for its excellent properties such as high temperature resistance, corrosion resistance, wear resistance, and low friction coefficient. This material can maintain stability under extreme conditions, working normally within a temperature range from extremely low -60 ℃ to as high as 260 ℃, which is crucial for the complex working environment inside automobiles. In addition, PTFE tubing is almost not corroded by any chemical substances, including strong acids, strong bases, and various organic solvents, which makes it perform well in handling media such as fuel and coolant.

2、 The Specific Application of Teflon Pipes in Automotive Manufacturing

(1). Engine and fuel system

The application of PTFE hose is particularly widespread in engines and fuel systems. As fuel and oil pipes, PTFE hose can effectively resist high temperatures and chemical erosion in fuel, ensuring stable fuel delivery. At the same time, its low friction characteristics reduce the resistance of fluid in the pipeline and improve the efficiency of the fuel system. In the intake system, PTFE air pipes can also prevent impurities and moisture from entering the system, keeping the engine clean and running efficiently.

(2). Cooling system

The excellent corrosion resistance and high temperature resistance make PTFE hose a potential choice for key components in cooling systems. Especially when facing corrosive coolant, PTFE hose can maintain their stable performance for a long time, providing strong guarantees for the reliable operation of the cooling system.

(3). Air conditioning system

High performance materials such as Teflon hoses are also required in automotive air conditioning systems. The air conditioning system has high requirements for the corrosion resistance and low friction coefficient of materials, and PTFE pipes precisely meet these needs. It can not only resist the corrosion of chemical substances in the refrigerant, but also reduce the friction loss of the air conditioning system, improve the refrigeration efficiency and reliability of the system.

3、 The Contribution of Teflon Pipes to the Automotive Industry

The application of PTFE hoses in automobile manufacturing not only improves the performance and reliability of vehicles, but also promotes the sustainable development of the automotive industry. Its excellent corrosion resistance and high temperature resistance reduce the failure and maintenance costs caused by material aging or corrosion, and extend the service life of the car. At the same time, the low friction characteristics of PTFE hoses reduce system energy consumption, improve fuel economy, and help reduce carbon emissions and protect the environment.

The application of PTFE hoses in automobile manufacturing has profound significance. It not only meets the high material requirements of the complex working environment inside automobiles, but also brings many benefits to the automotive industry through its unique performance advantages. We have reason to believe that Teflon tubing will continue to play an important role in the automotive industry, driving the development of automotive manufacturing towards greater efficiency, environmental friendliness, and sustainability.

Post time: Sep-06-2024