O-ring

Both SAE flange seals and O-ring end seals are sealed by O-rings. These fittings are generally used in applications with very high pressure and the reliability requirements for machinery equipment are also very high. These application occasions are generally static pressure seals. How can we ensure the reliability of O-ring seals

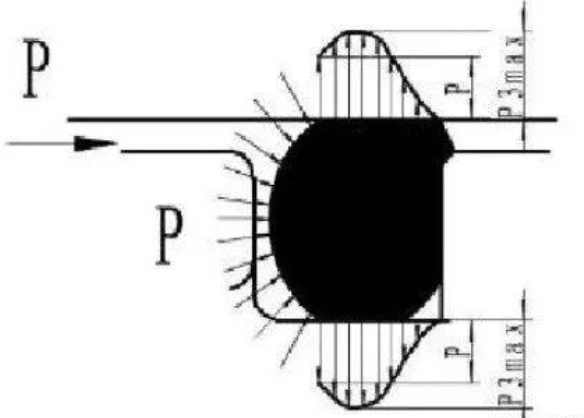

The sealing principle of O-rings used in static pressure sealing

After the O-ring is installed in the sealing groove, its cross-section is subjected to contact pressure, resulting in elastic deformation, and generates a initial contact pressure P0 on the contact surface. Even without medium pressure or with very little pressure, the O-ring can achieve sealing relying on its own elastic pressure. When the cavity is filled with pressurized medium, under the action of the medium pressure, the O-ring moves towards the low-pressure side, and its elastic further increases, filling and closing the gap. Under the action of medium pressure, the contact pressure Pp transmitted to the acting surface by the O-ring increases the acting on the contact surface of the sealing pair to Pm.

Initial pressure at the time of initial installation

The medium pressure is transmitted through the O-ring.

Composition of contact pressure

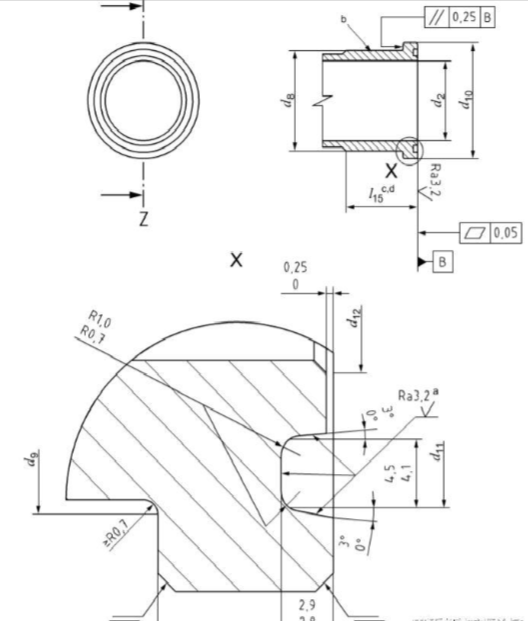

Taking the face-sealing O-ring tube fitting as an example, discuss the factors affecting the sealing of the tube fitting.

First, the seal should have a certain amount of installation compression. When designing the size of the O-ring seal and the groove, an appropriate compression should be considered. The standard O-ring seal sizes and corresponding groove sizes are already specified in the standards, so you can choose according to the standards

The surface roughness of the seal groove should not be too large, generally Ra1.6 to Ra3.2. The higher the pressure the lower the roughness should be.

For high-pressure sealing, in order to avoid the seal being extruded out of the gap and causing failure, the gap should be as small as. Therefore, it is necessary to ensure the flatness and roughness of the contact surface on the low-pressure side of the seal. The flatness should be within 0.05mm, and the roughness should be within Ra1.6.

At the same time, since the O-ring seal relies on the liquid pressure to transmit pressure to the O-ring seal and then to the bee contact, there should be a certain gap on the high-pressure side of the seal, which is generally between 0 and 0.25 mm.

Post time: Oct-31-2024