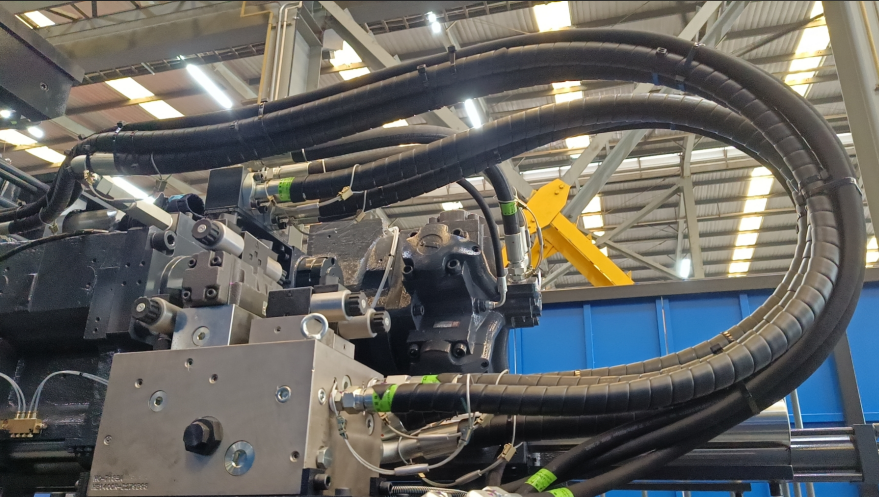

The quality of the hydraulic system of injection molding machine depends not only on the rationality of system design and the performance of system components, but also on the protection and treatment of system pollution, it is directly related to the reliability of the hydraulic system of injection molding machine and the service life of components.

1.Contamination and wear of components

Various contaminants in the oil lead to various forms of parts wear, solid particles into the clearance of the motion pair, resulting in parts of the surface cutting wear or fatigue wear. The impact of solid particles in high-speed liquid flow on the surface of parts results in erosion wear. Water in oil and the products of oil oxidation and deterioration can corrode parts. In addition, air in the system oil causes cavitation, resulting in surface erosion and destruction of components.

2. Component clogging and clamping failure

The particles block the clearance and orifice of the hydraulic valve, resulting in plug and jam of the valve core, affecting the performance, and even leading to serious accidents.

3.Accelerate the deterioration of oil properties.

Water and air in oil are the main conditions for oil oxidation due to their thermal energy, and metal particles in oil play an important catalytic role in oil oxidation. In addition, water and suspended bubbles in the oil can significantly reduce the oil film strength between the pairs, thus reducing the lubrication performance.

The type of pollutant

The contaminant is the harmful substance in the hydraulic system oil of the injection molding machine. It exists in oil in different forms. According to its physical form, it can be divided into solid pollutants, liquid pollutants and gas pollutants.

Solid pollutants can be divided into hard pollutants, including: Diamond, Chip, silica sand, dust, wear metal and metal oxide; Soft contaminants include additives, water condensate, oil breakdown products and polymers, and cotton and fiber brought in during maintenance.

Liquid contaminants are generally tank oil, water, paint, chlorine and its halides that do not meet the requirements of the system. In general, it‘s hard to get rid of them. So in the choice of hydraulic oil, to choose hydraulic oil in line with the system standards, to avoid some unnecessary failures.

Gaseous pollutants are mainly air mixed into the system.

These particles are usually small, unsettling, suspended in oil and eventually squeezed into the cracks of various valves. For a reliable injection molding machine hydraulic system, these clearances are critical to achieving limited control, importance, and accuracy.

Post time: Oct-22-2024