Today I would like to talk about the“Hose use standard” and those things! Altogether six points, let me tell you now

One:rubber hose use notice

(1) stress

1.Be sure to use hoses within the recommended temperature and pressure range.

2. The hose expands and contracts with internal pressure. Cut the hose to a length slightly longer than you need.

3.When applying pressure, open/close any valve slowly to avoid shock pressure.

(2) fluid

1, the use of hose to be suitable for the delivery of fluid.

2.Please consult US before using the hose for oil, powder, toxic chemicals and strong acids or alkalis.

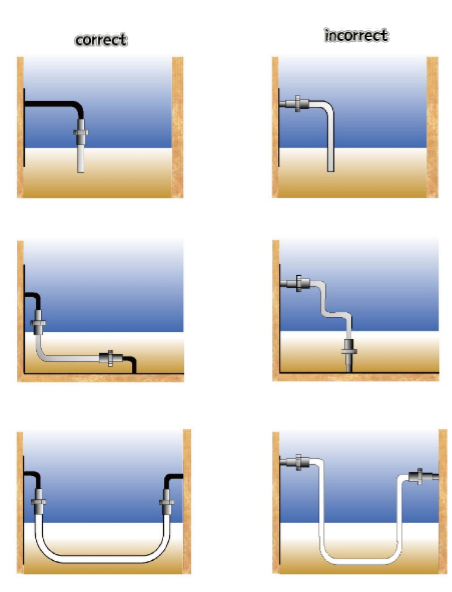

(3) Bend

1, please use the hose in its bending radius above the conditions, otherwise it will cause the hose broken, reduce the pressure.

2, when using powder, particle, according to the conditions may produce wear phenomenon, please maximize the bending radius of the hose.

3. Do not use near the metal parts (joints) under the condition of critical bending, and try to avoid the critical bending near the metal parts, which can be avoided by using elbow.

4, do not move the installed hose at will, especially to avoid the movement of hose joints caused by force or bending transition.

(4) other

1. please do not put the hose direct contact or near the fire

2. Do not press the hose with equal pressure of the vehicle.

Second, the Assembly of the matters needing attention

(1) metal parts (joints)

1, please choose suitable hose size hose connector.

2. When inserting the end part of the joint into the hose, put oil on the hose and the end of the hose. Do not roast the hose. If can not be inserted, hot water can be used to heat the hose after the insertion of the joint.

3. Please insert the end of the saw-tooth tube into the hose.

4. Do not use a push-in connector, which may cause the hose to break

(2) other

1. Avoid over-ligating with wire. Use a special sleeve or tie.

2. Avoid using damaged or rusted joints.

Third, the inspection of the matters needing attention

(1) pre-use inspection

Before using the hose, please make sure that there is no abnormal appearance of the hose (trauma, hardening, softening, discoloration, etc.) .

(2) regular inspection

During the use of the hose, be sure to carry out regular inspection once a month.

Specifications for cleaning sanitary grade hoses

Sanitary Hose is special, cleaning is also very special, before using sanitary hose, must flush the hose to ensure that the installation and use of the ideal sanitary conditions. The cleaning recommendations are as follows:

1. The hot water temperature is 90 ° C, the steam temperature is 110 ° C (this kind of hose cleaning time is less than 10 minutes) and 130 ° C (this kind of hose high-temperature cleaning 30 minutes) two kinds, the concrete is subject to the product engineer’s suggestion.

2. Nitric acid (HNO _ 3) or nitric acid content cleaning, concentration: 85 ° C is 0.1% , normal temperature 3% .

3. Chlorine (CL) or chlorine-containing ingredients cleaning, concentration: 1% temperature 70 ° C.

4.Wash with sodium hydroxide (NaOH) or sodium hydroxide at a concentration of 2% at 60-80 â ° C and 5% at room temperature.

FIVE:Safety

1.Under certain conditions, the operator should wear safety protective clothing, including gloves, rubber boots, long protective clothing, goggles, these equipment is mainly used to protect the safety of the operator.

2.Make sure your workspace is safe and organized.

3.Check the joints on each pipe for solidity.

4. When not in use, do not keep the pipe in a pressure-resistant state. Closing the pressure can extend the service life of the pipe.

SIX:Installation diagram of hose assembly (operating method of hose bending radius)

In the world of hoses, there are a lot of skills and application specifications, I hope you can be useful! You are also welcome to ask questions, to explore together!

Post time: Aug-14-2024