Here is a detailed comparison of 304SS and 316L stainless steel metal hoses:

Chemical composition and structure:

304SS stainless steel is mainly composed of chromium (about 18%) and nickel (about 8%) , forming austenitic structure, with excellent corrosion resistance and processability.

316L stainless steel adds molybdenum to 304, usually containing chromium (about 16-18%) , nickel (about 10-14%) , and molybdenum (about 2-3%) . The addition of molybdenum significantly improved its resistance to chloride corrosion, especially in the environment containing chloride ions。

Corrosion resistance:

304SS stainless steel has good corrosion resistance to general environment and most chemicals, but its corrosion resistance may be challenged in some specific acid or salt environment.

316L stainless steel is more resistant to chloride ions and various chemical media due to its molybdenum content, especially in marine environment and high salinity industrial applications.

Application:

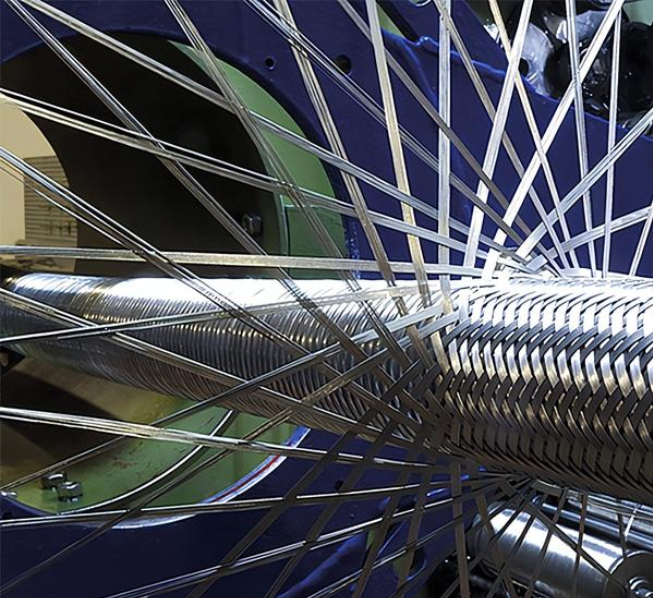

304SS stainless steel hose is widely used in chemical, petroleum, power, machinery and other industries, for the transmission of water, oil, gas and other media. Because of its good comprehensive performance, it is often used in kitchen utensils, food processing equipment and other fields.

Because of its excellent corrosion resistance and strength, 316L stainless steel hose is often used in places requiring more materials, such as pipeline connection for chemical equipment, transportation system for pharmaceutical equipment, ocean engineering, etc. .

Physical properties:

Both have high strength and toughness, but 316L stainless steel may have higher strength and better heat resistance due to the increase of alloying elements.

The oxidation and creep resistance of 316L stainless steel is usually better than 304SS at high temperature.

Price:

Because 316L stainless steel contains more alloy elements and better properties, its manufacturing cost is usually higher than 304SS, so the market price is relatively high.

Machining and installation:

Both of them have good machining performance, and can be processed by bending, cutting and welding.

In the installation process, both need to take care to avoid strong impact or pressure, so as not to cause damage to the equipment itself.

There are significant differences between 304SS and 316L stainless steel metal hoses in many aspects. In addition to cost considerations, the choice should be balanced against the specific application environment, media type, and performance requirements. For the general environment and media, 304SS may be an economical and practical choice, while 316L may be more appropriate in environments where higher requirements for corrosion resistance and strength are required.

Post time: Sep-20-2024